An hour-and-a-half drive northwest from bustling Milan, Italy’s undisputed epicenter of fashion, lies sleepy Roccapietra, population 639, nestled in the lush green foothills of the Italian Alps. What the village lacks in physical size, it quietly makes up for in clout as home to the Loro Piana textile mill.

The luxury fabric maker is the veritable wizard behind the fashion world’s figurative curtain, which would undoubtedly be constructed of Loro Piana cashmere and wool if it actually existed. Over an average of five days, around 100 employees working in three shifts at the Roccapietra factory shepherd cashmere and wool fibers as they twist and turn through a mélange of machinery. The finished yarns ultimately become textiles Loro Piana and many other prestigious fashion houses, tailors and couturiers rely on for their designs.

Long before clients swaddle themselves and their homes in Loro Piana cashmere and wool, the production process begins in the far-flung corners of the globe. In a once-in-a-lifetime event, herders in Mongolia and northern China comb out the soft inner coats of baby Capra Hircus goats that are between 3 and 8 months old, yielding a single ounce of downy delicate strands destined to be woven into Loro Piana’s signature baby cashmere.

One sweater can use up to 19 ounces of the prized fabric and cost as much as an ounce of gold. In spring, herders also collect the soft white under-fleece of adult Capra Hircus, which, by comparison, annually yield around 7 ounces of raw material. The cashmere is locally cleaned and inspected for impurities, such as hard-to-die dark hairs, and then checked a second time shortly before the lots are shipped to Roccapietra in giant burlap bales, or lots.

Raw vicuña and merino wool arrive in Italy the same way from three countries in the southern hemisphere. What is known as Loro Piana’s famed Gift of Kings wool comes from a special strain of merino sheep raised in Australia and New Zealand. The vicuña, a camelid that’s a distant relative of the llama and lives in the wild high in Peru’s Andes Mountains, can only be shorn of its coat every two or three years. Each vicuña produces around 8 ounces of fleece. The difference between merino and vicuña wool — considered the rarest animal fiber in the world — is only visible under an electronic microscope.

If the raw wool and cashmere are the grapes, scientists at Loro Piana’s Quarona factory, a short drive from the mill in Roccapietra, are the sommeliers. These experts methodically analyze fiber samples on a microscopic level to determine if the cashmere and wool shipments arriving from the five countries meet the company’s strict standards.

Once approved, the cashmere and wool are then ready to be blended for several hours in a giant mixing machine. Tumbling the fibers with water and oil adds moisture as well as opens and mixes the raw material until it takes on a light and soft consistency similar to clumps of stretched-out cotton balls.

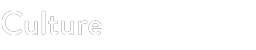

The wads of fibers are shot through pneumatic tubes to carding machines, where they are disentangled and cleaned. Using technology that hasn’t changed since the early 1940s, the raw material is fed through the oldest machine in the mill that gently turns the fibers into continuous diaphanous veil-like sheets that roll along hundreds of wooden rods and curl through metal drums. The machine folds the cleaned individual sheets multiple times into an increasingly thicker but still delicate cloudlike mass of fibers that resembles one long — and very expensive — foam cushion.

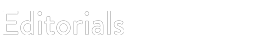

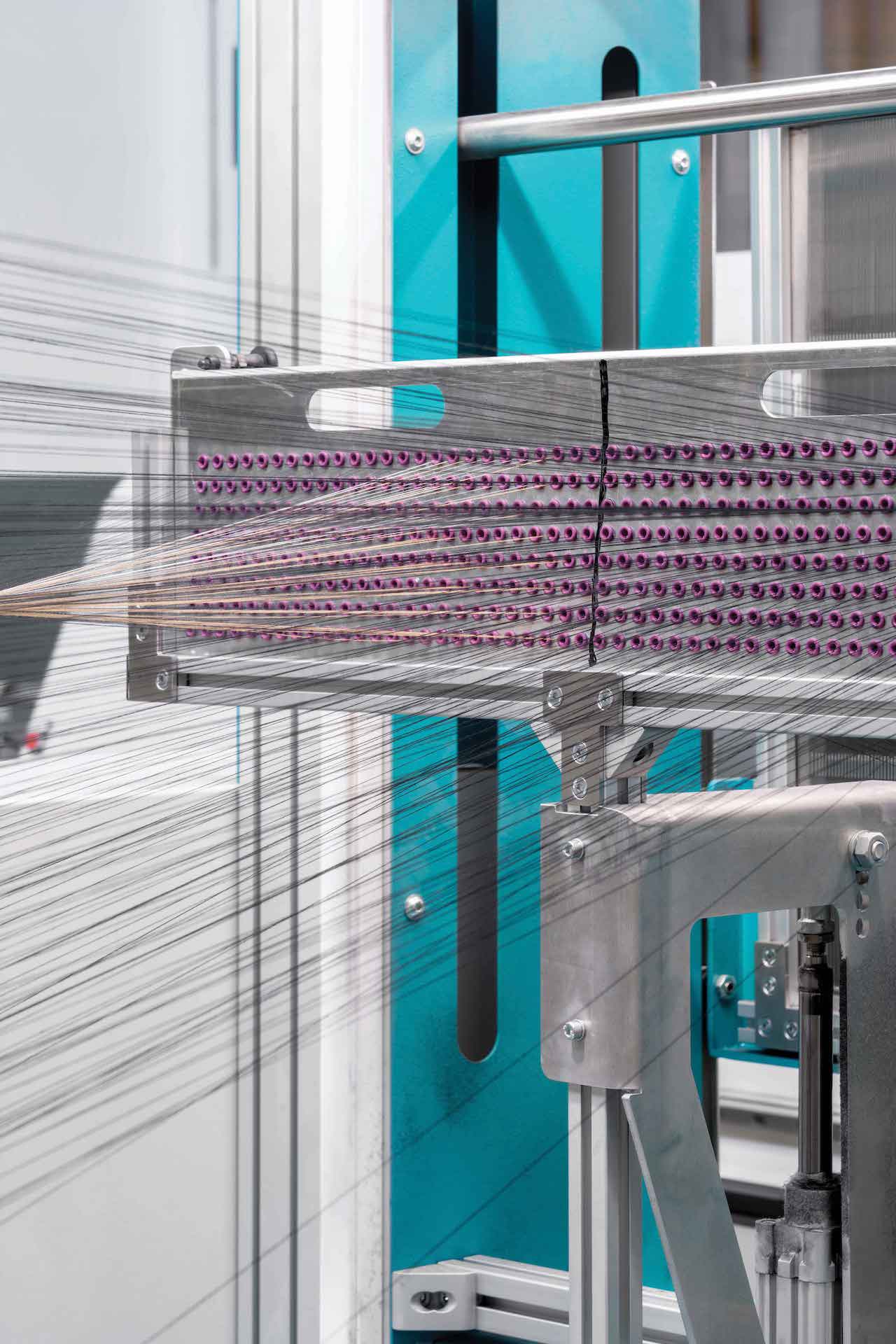

A spinning machine twists this mass of fibers into strands to create the yarn. The process is so precise that once the yarn is in its final form, machines checking the spools automatically cut out any strands with imperfections and fuse them back together. Expert eyes in the laboratory then check the yarn again to ensure no unacceptable defects still exist.

Once complete, some yarn is woven into fabric on looms and treated at the Quarona factory with a multi-step finishing process. Workers wash the fabric and extract the delicate fibers as well as mechanically shave the material so the surfaces of the fabrics are uniform in length.

GRAZIA USA’s 2022 Fall issue will be available for purchase on newsstands nationwide in October. Email [email protected] to subscribe.

The knowledge needed to grow Loro Piana into the brand internationally recognized as the pinnacle of textile manufacturing was developed over the course of six generations. The Loro Piana family began working as wool merchants in the early 19th century, and Pietro Loro Piana eventually established his eponymous company in April 1924. His nephew, Franco Loro Piana, took the reins in 1941, and he specialized in providing wool and cashmere textiles to the burgeoning haute couture industry. Beginning in 1970, his sons, Sergio and Pier Luigi Loro Piana, helmed the company and focused their efforts on gathering only the rarest materials as they built the luxury side of the brand LVMH bought for $2.6 billion in 2013.

The value of the business is evident in the care workers continue to put into the art of textile production, down to the final step. At the end of the process, they do another check, which is called fine-mending, where every meter of textile is inspected and every little imperfection is eliminated. Around 80 experts painstakingly remove miscolored fibers or mend tiny snags in the fabric, a process that usually takes five hours for each 100 meters of material.

On a recent day at the Quarona factory, a giant bolt of magenta textile woven with Louis Vuitton’s interlocking L and V logo and floral pattern sat near a mechanical loom turning tan- and brown-hued yarn into a similar stretch of fabric for the fashion house. These and up to as much as 25,000 square meters of impeccable textiles flowing out of Loro Piana’s factories daily will end up as an array of luxury products. Many will fall under the Loro Piana label — from sunny, bright yellow Loro Piana Interiors cushions and blankets at Splendido Mare, a seaside Belmond Hotel in Portofino, Italy, and trellis- patterned aprons waiters wear at the property’s DaV Mare restaurant, to plush, understated Loro Piana-branded cashmere sweaters lining the shelves of chic boutiques in Tokyo, New York and across the globe.

Loro Piana’s meticulous textile-making process, honed and refined over time, ensures fabrics bearing the brand’s label are fit each step of the way as they slowly transform from fleece to their final form. Workers follow the speed of the cashmere, not the speed of production. With Loro Piana, it turns out, you really can’t rush perfection.

GRAZIA USA’s 2022 Fall issue will be available for purchase on newsstands nationwide in October. Email [email protected] to subscribe.